Juice blending –

In today’s world, beverage processing must be more efficient and sustainable than ever before. By reinventing the standard JNSD processing line, Maria Norlin, Sub-category Manager for JNSD & Beverage and her team at Tetra Pak divided the process into two separate streams, one for concentrate and one for water.

This would help producers to minimise environmental impact while saving in both energy and water consumption – the story of this unmatched innovation unfolds below.

The JNSD portion of the beverage industry is stable and conservative in many ways, with industrial practices built up over decades to ensure product safety and production efficiency. However, a range of consumers trends – from increased concerns for health and calls for more natural alternatives to growing environmental awareness -– are putting pressure on JNSD manufacturing to rethink traditional practices.

We at Tetra Pak took the challenge and explored how we could make juice production more sustainable while maintaining product safety and shelf-life. We also wanted lower processing costs, to achieve these goals, we needed to find innovative solutions which save energy and water. And we did this by combining existing technologies-– filtration and UV treatment. Our experimentation and innovative equipment and processing parameters yielded extremely satisfying results.

This was the start of a long-term project to develop a low-energy JNSD line. Traditionally, we pasteurize the full volume (juice concentrate + water), where the most energy-intensive process step is heat treatment. In the new line, we pasteurize the smallest possible volume, the concentrate. The rest which is water is treated separately with more cost-effective aseptic technologies such as filtration and UV light. This new technology can greatly cut down heat treatments -– reducing energy consumption by about 67%. It also reduces water used in cleaning in place (CIP) and sterilization in place (SIP) by about 50%.

THE CHALLENGE: RETHINKING THE JNSD LINE WITH EXISTING TECHNOLOGIES

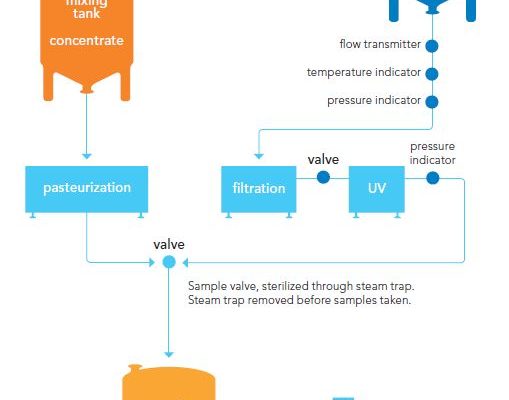

In JNSD solutions commonly used today (Figure 1), all ingredients are blended with water before going to the pasteurizer for heat treatment to deactivate harmful microorganisms. Even with modern pasteurizers though, which use regenerative heat to drive efficiencies, this is an energy-intensive approach which faces added challenges at scale. For instance, each product change in a large system volume of 2,000 litres is likely to create significant product loss and require additional, resource-intensive cleaning steps.

Informed by these challenges and past attempts to address them –- such as adding water to the concentrate as steam and then diluting it with cold water -– we decided to pursue a completely new approach. By leveraging existing technologies and the natural properties of water, we reinvented the traditional, resource intensive JNSD line and split it into two streams: one for water and one for concentrate and pre-mixes.

Unlike JNSD products, water is a clear liquid, which makes it very suitable for UV light treatment to ensure the required reduction of pathogens. Water is also free from cloud, particles, and the pulp typically found in juices and juice-based beverages, which allows for filtration that targets spoilage organisms.

In our new line concept, these lower-energy processes (i.e. UV light and filtration) are used to purify the water first, before it is blended with the concentrate –- which is still treated by heat, but at a greatly reduced volume (about 30%) given the absence of water.

THE OUTCOME: LESS ENVIRONMENTAL IMPACT, MORE OPERATIONAL SAVINGS

To verify that our new line concept met the formal test requirements we had established, we built a test plant and ran an operational test with nearly 8,000 juice packages.

As the summary table demonstrates, pilot testing was highly successful. The required log reductions for food safety and food spoilage were achieved –- and surpassed -– with a combination of filters and UV treatment. Our targets for reduced operational cost were also met, with yearly savings estimated at 92 thousand Euros when assuming a production time of 20 hours a day, 5 days a week.

In terms of investment costs, based on the filtration and UV equipment we selected, our new JNSD line was only 5% more expensive than the current solution. Accounting for operational savings, this investment cost would be paid back before our ROI target of a maximum of 6 months.

Importantly, beyond surpassing our food safety targets and showcasing operational costs savings of 67% relative to current solutions, pilot testing underscored significant sustainability gains – which were also a key focus area of ours.

At Tetra Pak, we are committed to helping drive more environment-friendly processing solutions – which are also in high demand from our customers given heightened consumer awareness around sustainability and increasing demands for businesses to take climate actions.

To that end, in developing this new line, we set targets of reducing water consumption by 25% and energy consumption by 40%, both of which we surpassed. In pilot testing, energy consumption was estimated to reduce by 67% and water consumption by 50% from 96,000 l/week to 48,000 l/week. By processing ingredients in two separate streams, whereby only 30% of the volume is heat treated through pasteurization, producers are better equipped to meet one of modern manufacturing’s most common challenges: producing more, with less.